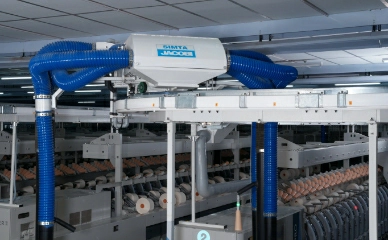

From a unique product innovation to a significant global presence, from one product improvisation to the entire product category, from a joint-venture partnership between India and Germany, to every corner of the world, our leap into the world of OHTCs was a significant intervention to the textile machinery manufacturing industry.

Compatibility is key when it comes to OHTCs. As trusted Overhead travelling cleaner manufacturers, SIMTA Jacobi ensures that its OHTCs function effortlessly across a wide range of machinery — including speed frames, ring spinning frames, auto and manual cone winders, doubling machines, open end spinning machines, warping and twisting machines, Airjet Spinning Machine, chenille machines, end wall cleaning, and weaving machines.

Applications

SIMTA JACOBI OHTC units are designed, developed and tested across different applications—spinning, weaving, straight or curved path:

- Belt Drive System (Model STB 15) for single machine

- Chain Drive System ( Model STB 15) for single machine

- Power Duct Bus Bar System ( Models - STC20 , STW50) for single machines and group of machines

As leading OHTC Belt Drive Model Manufactures in Coimbatore, we offer robust and efficient solutions tailored to meet the specific needs of each machine configuration.

Wall cleaning. Speed Frames and weaving machines

- SIMTA JACOBI OHTC for Speed Frames guarantee a high degree of cleanliness by providing continuous blowing and suction to the drafting system, flyer zone and critical areas

- A very special arrangement to suck / collect waste generated from the positive clearer ensures best possible condition for the roving

- When a speed frames stops due to slubbing break, the fan motor stops immediately n case of group of machines

- The fan motor will be re-activated for clearing the remaining speed frames

Features

- Energy efficient motor for low power consumption

- CNC Turret Punch Press and CNC Laser Cutting machines ensure precision metal cutting

- Facilitates interchangeability

- Special die from M/s JACOBI, Germany for the current collector ensures extended life of feeding mechanism

- Aero dynamic design with uniform airflow results in better and enhanced suction and blowing

- Push button on both sides for Start, Stop and Reversal of the unit

- Latest generation programmable Logic Controller (PLC) OR PCB for effective control operations such as customised time adjustment for discharge and reversal

Optional

- Auto Parking at one end during doffing

- Link coner arrangement with separate blowing for spinning and autoconer

- Wharve cleaning facility

- Rocos/ Compact yarn / Elite nozzle suction arrangement

- Automatic / Manual waste collection system

- Obstacle sensor / Limit switch for safety during obstruction

Weaving Features

- Double side discharge results in effective cleaning and higher performance

- Specially designed for enhanced blowing and suction

- Suitable for straight line and curved path

- Can be enabled to skip non-operational looms in circular / straight or curved path

- More filter screen area for higher efficiency

- Blowing adjusted in individual blowing pipes

Products

-

Textile Machinery and Accessories Division

- Spindle Tapes

- Flocked Clearer Rollers

- Flocked Clearer Roller Cleaning Machines

- OHTCs

- Bobbin Transport Systems

- Cone Transport Systems

- Auto Packing

Technical Specification

| PROPERTIES | STS 15 | STB 15 | STC 20 | STW 50 |

|---|---|---|---|---|

| Fan Motor | 3HP, 3Ø, 415 Volts | 2HP Or 3HP, 3Ø, 415 Volts | 3HP Or 4HP, 3Ø, 415 Volts | 5HP, 3Ø, 415 Volts |

| Drive Motor | 150 Watts, 3Ø, 415 Volts | -- | 150 Watts, 3Ø, 415 Volts | 180 Watts, 3Ø, 415 Volts |

| Blowing Air Volume | 2250 M3 / Hours | 2000 M3 / Hours | 2000 M3 / Hours | 2000 M3 / Hours |

| Suction Capacity (U - Tube) | 210mm Of Water Column | 150mm Of Water Column | 250mm Of Water Column | 250mm Of Water Column |

| No Of Blowing Pipes X Size | 2 X 125 Mm | 2 X 125 Mm | 2 X 125 Mm | 12 X 75mm |

| No Of Suction Pipes X Size | 4 X 100 Mm | 4 X 100 Mm | 4 X 100 Mm | 4 X 100 Mm |

| Travelling Speed | 16 Mtrs / Minutes | 11 Mtrs / Minutes | 16 Mtrs / Minutes | 16 Mtrs / Minutes |

| Filter Area | 0.14 Sq.Mtr | 0.16 Sq.Mtr | 0.14 Sq.Mtr | 0.28 Sq.Mtr |

| Travelling Path | Straight | Straight | Straight, Curved & Circular | Straight, Curved & Circular |