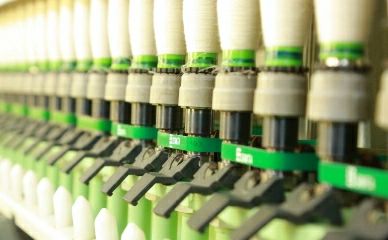

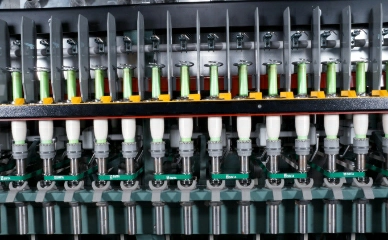

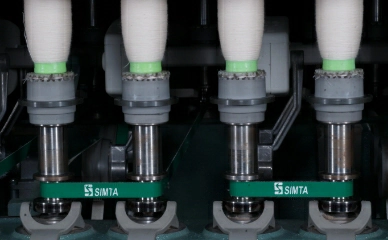

A leap from a small-scale manufacturer of spindle tapes to leaders in the market with a 50% lead share — that’s the journey of Simta spindle tapes in India. From innovations that enhance spindle performance to unmatched durability, and from using the finest raw materials to consistently improving functionality, Simta spindle tapes are all this and more.

- Designed for negligent slippage and elongation and consistent performance

- Unique interventions

- A specially formulated rubber compound that eliminates abrasion of the ABS tin roller pulley

- An adhesive that ensures super smooth joints

- Designed to maximise performance through undisturbed speed in the event of individual piecing

- No load on the jockey pulley and spindles, ensuring no elongation

- Customised to specific requirements in various grades and width ranges

- High-quality fabric and chemicals for durability, uniformity, and consistent performance

- Uniformity and consistency retained throughout the lifespan

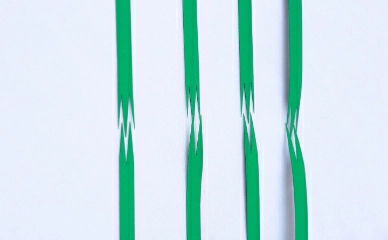

- Skived ends for uniform thickness

Polyamide

Grades - SS1, SS-2, SS-3, SS-4, SS-5, SS-55

- Excellent performance even at 25,000 rpm

- 60% production exported to more than 50 countries

- OEM suppliers to leading textile mills across the world

Polyurethane

Grades - S-8

- Extensive tests carried out on S-8 tapes with different models and parameters

- Higher power transmission ability with power saving of 2–6%

- Designed for new generation ring spinning frames

- Low energy consumption

- No fibre / fluff accumulation throughout the life

- Constant spindle speed, minimum vibration on spindle wharves

- Uniform / consistent yarn quality

- Suitable for S and Z directions

- Negligible vibration in speed when one spindle stops

- 2 to 3 % energy savings of ring frame main motor consumption

- Investment payback within 5 - 6 months

Products

-

Textile Machinery and Accessories Division

- Spindle Tapes

- Flocked Clearer Rollers

- Flocked Clearer Roller Cleaning Machines

- OHTCs

- Bobbin Transport Systems

- Cone Transport Systems

- Auto Packing

Technical Specification

| PROPERTIES | SS-1 | SS-2 | SS-3 | SS-4 | SS-5 | SS-55 |

|---|---|---|---|---|---|---|

| THICKNESS (MM) | 0.56 | 0.75 | 0.60 | 1.00 | 0.61 | 1.10 |

| BREAKING STRENGTH (± 5 Kgs) | 71 | 95 | 82 | 175 | 85 | 190 |

| ELONGATION (%) AT 1 Kg | 0.525 | 0.490 | 0.490 | 0.370 | 0.490 | 0.370 |

| 2 Kg | 1.050 | 1.000 | 0.975 | 0.536 | 0.975 | 0.536 |

| 3 Kg | 1.650 | 1.500 | 1.350 | 0.806 | 1.350 | 0.806 |

| WT. PER MTR (Gm / Cm) | 5.00 | 7.00 | 5.10 | 11.5 | 5.20 | 11.5 |

| NORMAL PERIPHERAL FORCE PER UNIT WIDTH (Kg/Cm) | 3.5 | 6.5 | 4.2 | 8.5 | 4.3 | 8.6 |

| OPERATING TEMPERATURE (°C) CONTINUOUS | -20 TO 100 | -20 TO 100 | -20 TO 100 | -20 TO 100 | -20 TO 100 | -20 TO 100 |

| INTERMITTENT | -30 TO 170 | -30 TO 170 | -30 TO 170 | -30 TO 170 | -30 TO 170 | -30 TO 170 |

| CO-EFFICIENT OF FRICTION ON STEEL PULLEY SIDE (Μ) | 0.55 | 0.55 | 0.70 | 0.70 | 0.70 | 0.70 |

| WHARVE SIDE (Μ) | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

| LENGTH TOLERANCE (%) | ±0.50 | ±0.40 | ±0.40 | ±0.40 | ±0.40 | ±0.40 |

| WIDTH TOLERANCE (MM) | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 | ±0.25 |

| APPLICATION | SPG & DBG SPINDLE RPM UP TO 20,000 | TFO AND HEAVY DOUBLING | SPG & DBG SPINDLE RPM UP TO 25,000 | TFO AND HEAVY DOUBLING(HIGH SPEED) | SPG & DBG SPINDLE RPM UP TO 25,000 | TFO AND HEAVY DOUBLING(HIGH SPEED) |